I'm currently working on a top secret* contraption involving some bits of wood and some bike wheels.

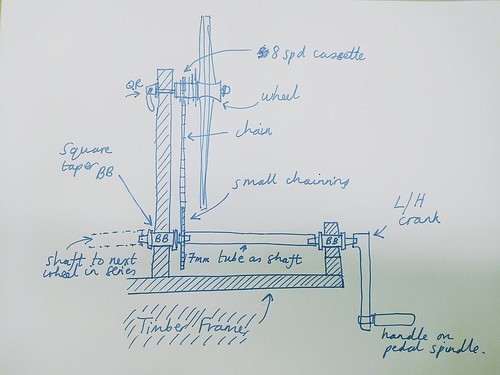

The contraption involves the bike wheels rotating. This could be done by handspinning the wheel but ideally I'd like it to be done by a hand crank. One is an old rear wheel freehub which my intention would be to put a chain on linked to a sprocket and then turn that by means of a driveshaft with a crank and handle at the end.

So my question is, does anyone have any suggestions as to how to interface a bicycle sprocket with a piece of steel rod which could act as my driveshaft? Or any suggestions as to something light and readily available which might work as a driveshaft/crank/handle.

Ideally it's something that is low cost, I can do from readily available (or even better free/recycled/repurposed bicycle components) and which doesn't involve welding.

It's all fairly low speed/low load so I'm not too concerned about it being structurally impressive or even that true, I can get away with a certain amount of wobble and misalignment..

* - for now, until I can actually make the thing work at which point I will post details and photos here for all to admire.

resolved

resolved

?

?

posts

posts